In the high-end manufacturing field, the leveling accuracy of sheet metal directly determines the quality of end products, and intelligence is the core lever to improve production line efficiency. Top domestic manufacturers have achieved dual breakthroughs in core technology through years of technological accumulation. On the one hand, in the core technology of hydraulic leveling, enterprises have generally overcome difficulties such as precise control of dynamic pressure in hydraulic systems and multi-sensor data fusion. The intelligent hydraulic servo control system launched can achieve precision adjustment of 0.01mm level, far exceeding the 0.05mm level standard of traditional equipment, and can fully meet the strict requirements of new energy vehicle battery shells, aerospace precision components, etc. for plate flatness.

On the other hand, the deep integration of intelligent technology allows devices to break free from the limitations of "single machine operation". Mainstream manufacturers have integrated equipment with visual inspection modules and data acquisition terminals, which can monitor parameters such as board flatness and thickness deviation in real time and synchronize them to the central control system of the production line; Simultaneously supporting seamless integration with management systems such as MES and ERP, building a fully automated closed-loop process from raw material loading to finished product sorting. The technical director of a certain manufacturer revealed that the new energy vehicle parts production line they delivered has been verified to increase the pass rate of plate leveling to 99.8% and the overall efficiency of the production line by 35%, which has reached the international top level.

Industry News

Dual Core Technology Breakthroughs: Intelligent Hydraulic Leveling Leads High-End Sheet Metal Processing to New Heights

Recommended Products

-

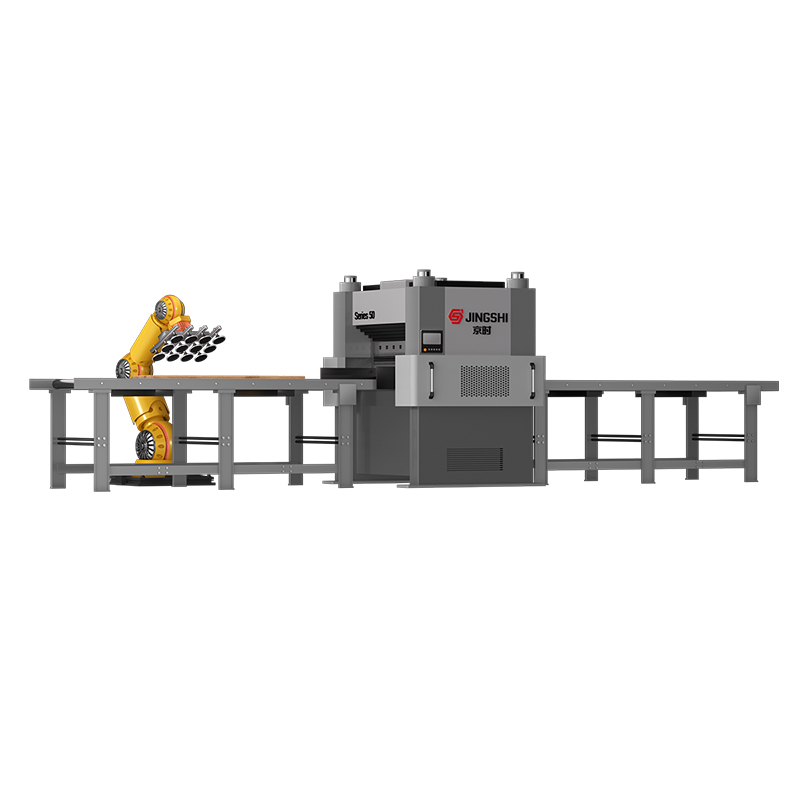

50 Series Four-Column Hydraulic Intelligent Precision Leveling Machine

-

60 Series Thick Plate High-Efficiency Hydraulic Leveling Machine

-

40 Series Heavy-Duty Hydraulic Precision Leveling Machine

-

80 Series Heavy-Duty Plate Hydraulic Ultra-Precision Leveling Machine

-

100 Series Large Workpiece Hydraulic Precision Leveling Machine

-

30 Series Thin Plate Hydraulic Servo Precision Leveling Machine

English

English русский

русский Español

Español عربى

عربى