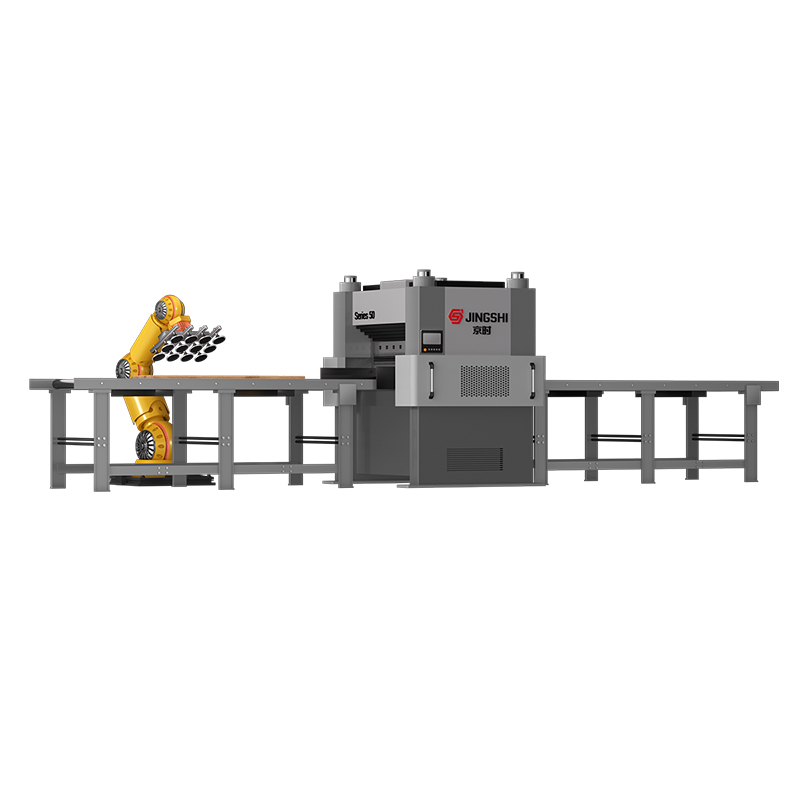

40 Series Heavy-Duty Hydraulic Precision Leveling Machine

Facing the processing of heavy sheet metal components such as engineering machinery structural parts, automotive chassis, and machine tool bed parts, the 40 series heavy-duty hydraulic precision leveling machine, with its robust rigidity, provides a solid guarantee for leveling 0.6-4mm thick metal sheets. Whether it's thick steel plates, high-strength alloy plates, or large stamped parts, its high-output hydraulic system (1.2-2.0Mpa) combined with a precision leveling mechanism of ≥13 rollers not only quickly corrects warping deformation after rolling and stamping but also controls flatness errors to ≤±0.01-0.05mm, far exceeding industry standards.

The HRC60-64 high wear-resistant and impact-resistant roller surface ensures a long service life for the equipment in batch processing of container plates, steel structures, etc., while the maximum processing width of 1600mm (customizable for wider applications) further expands its application boundaries. The graded pressure adjustment function can accurately adapt the pressure to different material hardnesses, the intelligent temperature control system avoids overheating during long-term operation, and the multiple safety interlock designs such as sheet metal deviation detection and overload protection make heavy sheet metal processing both efficient and safe, making it a trusted choice for industries such as construction machinery and automobile manufacturing.

- Specification

- About JINGSHI

- Contact Us

| Width of standard series | 600 | 900 | 1000 | 1300 | 1600 | 1900 | 2100 |

| Diameter of leveling roller | 40 | 40 | 40 | 40 | 40 | 40 | 40 |

| Number of leveling rollers | 23 | 23 | 23 | 23 | 23 | 23 | 23 |

| The shortest workpiece length for flattening Lmin (mm) | Lmin=80 | Lmin=80 | Lmin=80 | Lmin=80 | Lmin=80 | Lmin=80 | Lmin=80 |

| Nominal thickness of leveling material T (mm) | 0.6-4.0 | 0.6-4.0 | 0.6-4.0 | 0.6-4.0 | 0.6-4.0 | 0.6-4.0 | 0.6-4.0 |

| Maximum thickness of flattening material Tmax (mm) | Tmax=8 | Tmax=8 | Tmax=8 | Tmax=8 | Tmax=8 | Tmax=8 | Tmax=8 |

| Leveling accuracy | The parameters are calculated according to the material Q235/yield strength 235MPa, and the length and width are detected within 1m | ||||||

| 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | |

| Straightening line speed (m/min) | Speed adjustable at 1-10m/min | ||||||

| voltage | AC three-phase 380V | ||||||

| Optional Accessories | 1. Pulling out the flattening roller downwards (convenient for roller quick change and surface cleaning) | 4. Four/six times leveling roller | 7. Number of leveling rollers | ||||

| 2. Pulling out the leveling roller (convenient for roller quick change and surface cleaning) | 5. Automatic loading/unloading manipulator/palletizing robot | 8. Uncoiler - Hydraulic/Mechanical Cutting Line | |||||

| 3. Pulling out the roller up and down (convenient for roller quick change and surface cleaning) | 6. Feeding and discharging roller assembly line: with/without power | 9. Uncoiler - laser cutting blanking line | |||||

| Customized requirements | Customer customization requirements are acceptable | ||||||

| Remarks | Straighten the pressing gap of materials, input relevant parameters through the touch screen, and the equipment will automatically adjust. | ||||||

Our core team brings over a decade of expertise in metal forming and finishing, mastering system-level R&D from structural design to hydraulic control and automation integration. Steel Plate Leveling Machine Custom. We drive growth through technological innovation and continuous improvement.

Recommended Products

-

80 Series Heavy-Duty Plate Hydraulic Ultra-Precision Leveling Machine

-

50 Series Four-Column Hydraulic Intelligent Precision Leveling Machine

-

100 Series Large Workpiece Hydraulic Precision Leveling Machine

-

30 Series Thin Plate Hydraulic Servo Precision Leveling Machine

-

60 Series Thick Plate High-Efficiency Hydraulic Leveling Machine

-

Fixed Suction Cup Lifting Machine

Each machine undergoes comprehensive testing — including flatness precision, load performance, and noise assessment — to ensure long-term stability and reliability that meets international requirements.

-

Industry News

Industry News

2026.02.23

Crane components determine lifting safety, uptime, and load control. If you understand the key parts—especially the hoist, wire rope/chain, hooks, bra...

2026.02.23

Crane components determine lifting safety, uptime, and load control. If you understand the key parts—especially the hoist, wire rope/chain, hooks, bra... -

Industry News

Industry News

2026.02.16

What Is a Jib Crane? A jib crane is a lifting device with a horizontal rotating arm (the jib) that moves loads within a defined circular or semi-circ...

2026.02.16

What Is a Jib Crane? A jib crane is a lifting device with a horizontal rotating arm (the jib) that moves loads within a defined circular or semi-circ... -

Industry News

Industry News

2026.02.09

A leveler, also known as a leveling machine or roller leveler, is an industrial machine designed to flatten metal coils, sheets, and plates by elimin...

2026.02.09

A leveler, also known as a leveling machine or roller leveler, is an industrial machine designed to flatten metal coils, sheets, and plates by elimin... -

Industry News

Industry News

2026.02.02

Pascal's Law: The Foundation of Hydraulic Systems Hydraulic machines work under the principle of Pascal's Law, which states that pressure applied to ...

2026.02.02

Pascal's Law: The Foundation of Hydraulic Systems Hydraulic machines work under the principle of Pascal's Law, which states that pressure applied to ...

English

English русский

русский Español

Español عربى

عربى