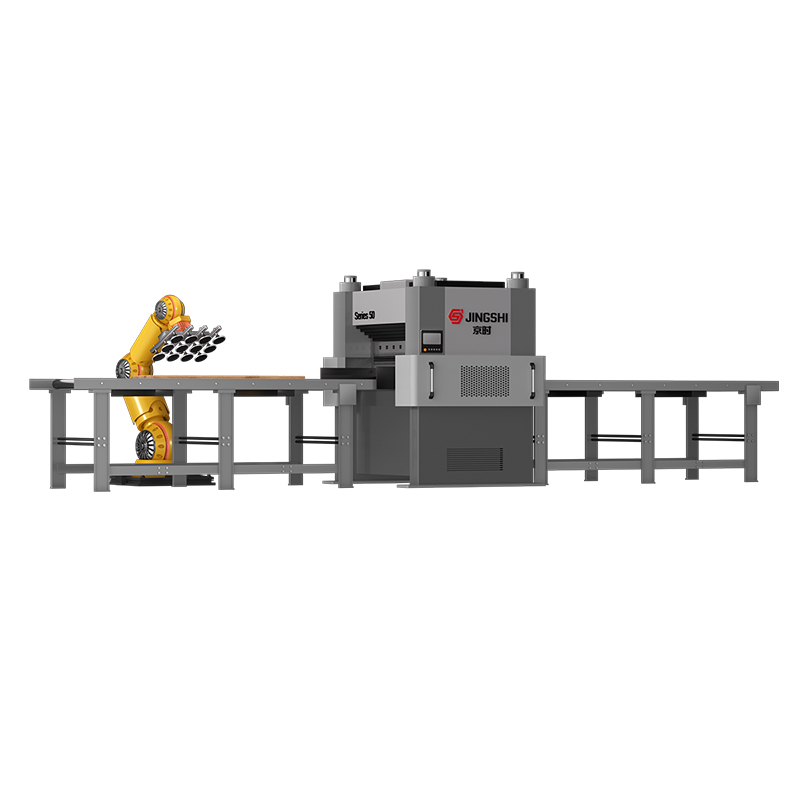

100 Series Large Workpiece Hydraulic Precision Leveling Machine

The 100 Series Large Workpiece Hydraulic Precision Leveling Machine is a high-end leveling equipment developed for ultra-thick and ultra-large metal workpieces. It adopts an integrated ultra-rigid body and a high-pressure hydraulic system, adaptable to workpieces 3-12mm thick. It can efficiently correct deep deformations caused by rolling, welding, and heat treatment, meeting the stringent flatness requirements of heavy-duty high-end manufacturing.

Core Positioning Module:

·Equipment Level: High-end flagship model, specifically developed for ultra-thick and ultra-large metal workpieces 3-12mm thick.

·Core Mission: To efficiently correct deep deformations caused by rolling, welding, and heat treatment, breaking through the bottleneck of high-precision leveling of large workpieces.

·Applicable Scenarios: Ship plate processing, engineering machinery frame leveling, wind power flange processing, pressure vessel leveling, rail transit structural component manufacturing, heavy-duty machine tool bed precision leveling.

Performance Advantage Module:

·Structural Stability: Integrated ultra-rigid body design, outstanding resistance to torsion and deformation, ensuring deviation-free processing of large workpieces.

·Precision Control: Combination of high-pressure hydraulics and servo control, leveling accuracy reaches ±0.01-0.05mm, breaking through the precision limitations of large workpieces.

·Efficiency Improvement: Optimized feeding and roller system layout improves efficiency by 20% compared to conventional large-scale equipment, adapting to large-scale mass production.

·Durability: Key components use imported materials, reducing wear rate by 40%, significantly extending maintenance cycles, and significantly reducing operating costs.

Key Parameter Overview:

·Processing Range: Thickness 15-30mm, maximum processing width ≤2100mm.

·Core Configuration: Multi-roller design (standard ≥21 rolls), roller surface hardness reaches HRC65-68, ultra-high wear resistance and impact resistance.

·Operating Efficiency: Processing speed 1-10m/min, hydraulic system pressure 3.0-4.0Mpa, stable power output.

Core Functional Modules:

·Intelligent Adaptation: Built-in intelligent deformation detection system, real-time matching of deformation amount and pressure adjustment for precise leveling.

·Convenient Operation: Industrial touch screen supports storage, retrieval, and data traceability of 200+ sets of process parameters, enabling efficient switching between multiple processing products.

·Safety Protection: Equipped with multiple safety systems including oil temperature monitoring, overload protection, and deviation alarm, eliminating operational risks.

·Flexible Adaptability: Supports fine-tuning of roller gap and machine body calibration; customizable feed guide device to adapt to various oversized workpieces.

- Specification

- About JINGSHI

- Contact Us

| Width of standard series | 600 | 900 | 1000 | 1300 | 1600 | 1900 | 2100 |

| Diameter of leveling roller | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Number of leveling rollers | 15/19 | 15/19 | 15/19 | 15/19 | 15/19 | 15/19 | 15/19 |

| The shortest workpiece length for flattening Lmin (mm) | Lmin=160 | Lmin=160 | Lmin=160 | Lmin=160 | Lmin=160 | Lmin=160 | Lmin=160 |

| Nominal thickness of leveling material T (mm) | 3.0-12.0 | 3.0-12.0 | 3.0-12.0 | 3.0-12.0 | 3.0-12.0 | 3.0-12.0 | 3.0-12.0 |

| Maximum thickness of flattening material Tmax (mm) | Tmax=30 | Tmax=30 | Tmax=30 | Tmax=30 | Tmax=30 | Tmax=30 | Tmax=30 |

| Leveling accuracy | The parameters are calculated according to the material Q235/yield strength 235MPa, and the length and width are detected within 1m | ||||||

| 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | 0.01-0.05mm | |

| Straightening line speed (m/min) | Speed adjustable at 1-10m/min | ||||||

| voltage | AC three-phase 380V | ||||||

| Optional Accessories | 1. Pulling out the flattening roller downwards (convenient for roller quick change and surface cleaning) | 4. Four/six times leveling roller | 7.Number of leveling rollers | ||||

| 2. Pulling out the leveling roller (convenient for roller quick change and surface cleaning) | 5. Automatic loading/unloading manipulator/palletizing robot | 8. Uncoiler - Hydraulic/Mechanical Cutting Line | |||||

| 3. Pulling out the roller up and down (convenient for roller quick change and surface cleaning) | 6. Feeding and discharging roller assembly line: with/without power | 9. Uncoiler - laser cutting blanking line | |||||

| Customized requirements | Customer customization requirements are acceptable | ||||||

| Remarks | Straighten the pressing gap of materials, input relevant parameters through the touch screen, and the equipment will automatically adjust. | ||||||

Our core team brings over a decade of expertise in metal forming and finishing, mastering system-level R&D from structural design to hydraulic control and automation integration. Hydraulic Roller Leveling Machine Custom. We drive growth through technological innovation and continuous improvement.

Recommended Products

-

40 Series Heavy-Duty Hydraulic Precision Leveling Machine

-

50 Series Four-Column Hydraulic Intelligent Precision Leveling Machine

-

80 Series Heavy-Duty Plate Hydraulic Ultra-Precision Leveling Machine

-

30 Series Thin Plate Hydraulic Servo Precision Leveling Machine

-

60 Series Thick Plate High-Efficiency Hydraulic Leveling Machine

-

Fixed Suction Cup Lifting Machine

Each machine undergoes comprehensive testing — including flatness precision, load performance, and noise assessment — to ensure long-term stability and reliability that meets international requirements.

-

Industry News

Industry News

2026.02.23

Crane components determine lifting safety, uptime, and load control. If you understand the key parts—especially the hoist, wire rope/chain, hooks, bra...

2026.02.23

Crane components determine lifting safety, uptime, and load control. If you understand the key parts—especially the hoist, wire rope/chain, hooks, bra... -

Industry News

Industry News

2026.02.16

What Is a Jib Crane? A jib crane is a lifting device with a horizontal rotating arm (the jib) that moves loads within a defined circular or semi-circ...

2026.02.16

What Is a Jib Crane? A jib crane is a lifting device with a horizontal rotating arm (the jib) that moves loads within a defined circular or semi-circ... -

Industry News

Industry News

2026.02.09

A leveler, also known as a leveling machine or roller leveler, is an industrial machine designed to flatten metal coils, sheets, and plates by elimin...

2026.02.09

A leveler, also known as a leveling machine or roller leveler, is an industrial machine designed to flatten metal coils, sheets, and plates by elimin... -

Industry News

Industry News

2026.02.02

Pascal's Law: The Foundation of Hydraulic Systems Hydraulic machines work under the principle of Pascal's Law, which states that pressure applied to ...

2026.02.02

Pascal's Law: The Foundation of Hydraulic Systems Hydraulic machines work under the principle of Pascal's Law, which states that pressure applied to ...

English

English русский

русский Español

Español عربى

عربى