Hydraulic Leveling Machine Manufacturers

-

30 Series Thin Plate Hydraulic Servo Precision Leveling Machine

-

40 Series Heavy-Duty Hydraulic Precision Leveling Machine

-

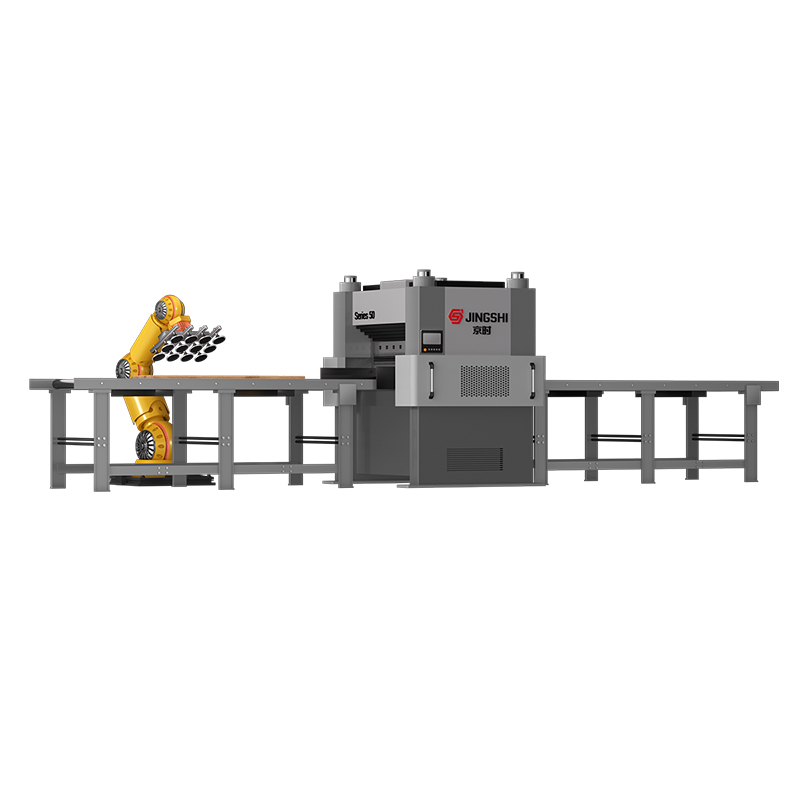

50 Series Four-Column Hydraulic Intelligent Precision Leveling Machine

-

60 Series Thick Plate High-Efficiency Hydraulic Leveling Machine

-

80 Series Heavy-Duty Plate Hydraulic Ultra-Precision Leveling Machine

-

100 Series Large Workpiece Hydraulic Precision Leveling Machine

Hydraulic leveling machines use hydraulic drive as their core power source, and are equipped with multiple sets of staggered leveling rollers (including working rollers, intermediate rollers, and support rollers). By precisely controlling the pressing force and the number of bending cycles, the metal sheet undergoes alternating "elastic-plastic" deformation, ultimately achieving the preset flatness requirements. This specialized equipment can process various metal materials (aluminum, copper, steel, titanium alloys, etc.) with thicknesses ranging from 0.1mm (ultra-thin copper foil) to 60mm (special alloy thick plates).

As Hydraulic Leveling Machine Manufacturers and Precision Leveling Machine Suppliers in China, our equipment is widely used in automotive parts, precision sheet metal, elevator components, agricultural machinery, saw blades, precision stamping, profile manufacturing, and electrical applications. Through continuous innovation and technical excellence, JingShi has become a trusted partner for manufacturers around the world.

-

Industry News

Industry News

2026.02.23

Crane components determine lifting safety, uptime, and load control. If you understand the key parts—especially the hoist, wire rope/chain, hooks, brakes, boom/jib structure, slewi...

2026.02.23

Crane components determine lifting safety, uptime, and load control. If you understand the key parts—especially the hoist, wire rope/chain, hooks, brakes, boom/jib structure, slewi... -

Industry News

Industry News

2026.02.16

What Is a Jib Crane? A jib crane is a lifting device with a horizontal rotating arm (the jib) that moves loads within a defined circular or semi-circular area. It’s designed for s...

2026.02.16

What Is a Jib Crane? A jib crane is a lifting device with a horizontal rotating arm (the jib) that moves loads within a defined circular or semi-circular area. It’s designed for s... -

Industry News

Industry News

2026.02.09

A leveler, also known as a leveling machine or roller leveler, is an industrial machine designed to flatten metal coils, sheets, and plates by eliminating internal stresses, warpi...

2026.02.09

A leveler, also known as a leveling machine or roller leveler, is an industrial machine designed to flatten metal coils, sheets, and plates by eliminating internal stresses, warpi... -

Industry News

Industry News

2026.02.02

Pascal's Law: The Foundation of Hydraulic Systems Hydraulic machines work under the principle of Pascal's Law, which states that pressure applied to a confined incompressible flui...

2026.02.02

Pascal's Law: The Foundation of Hydraulic Systems Hydraulic machines work under the principle of Pascal's Law, which states that pressure applied to a confined incompressible flui...

How roller diameter and pitch determine the “processable window”

Buyers often focus on nominal thickness range, but the practical boundary is set by the relationship between roller diameter, roller pitch (center distance), and the material’s yield strength. Smaller working rollers and tighter pitch increase bending frequency, helping eliminate short-wave defects; larger diameters increase load capacity and reduce surface marking risk on softer alloys.

What to check when comparing machine quotes

- Working roller diameter and pitch: smaller/tighter typically improves short-wave correction, but raises contact pressure.

- Intermediate/support roller adjustment method: mechanical vs hydraulic-assisted affects how well the machine holds crown control under load.

- Frame stiffness and tie-rod design: stiffness is a hidden driver of repeatability when processing high-strength steel.

- Surface protection strategy: for aluminum/copper, ask about roller finish and cleaning provisions to minimize pickup.

If you share your typical alloy grades and defect wavelengths, we can pre-match roller configuration to your real defect spectrum rather than relying on generic “thickness range” labels.

Flatness is not one metric: specify what you will measure and how

“Flat” can mean different things depending on whether your downstream process is stamping, laser cutting, or precision assembly. Procurement specs should define the measurement method (straightedge, optical, tension-level reference, CMM sampling), the sampling length, and the defect type you are controlling (edge wave, center buckle, coil set, crossbow).

| Specification element | Why it matters | Practical example |

|---|---|---|

| Sampling length / grid | Short sampling hides long-wave defects; long sampling hides short-wave ripples. | Measure over 1 m for plate; tighter grid for precision sheet. |

| Defect type naming | Different defects require different roller/pitch strategy. | Edge wave vs center buckle need different crown control. |

| Tension condition | Material can appear flatter under tension than in free state. | Define “free-state” flatness after unloading. |

| Temperature / lubrication state | Thermal growth and lubrication change friction and springback. | Verify at stable line temperature for repeatability. |

For high-precision buyers, the key is to align acceptance testing with your actual downstream sensitivity; the best leveling result is the one you can verify consistently.

Pressing force vs bending cycles: how to avoid “flat today, warped tomorrow”

Hydraulic levelers achieve flatness via alternating elastic-plastic deformation. Two levers dominate: (1) the pressing force distribution across the roller set and (2) the number of effective bending cycles. Over-driving force to “force flatness” can store residual stress and lead to later distortion after cutting, welding, or heat input.

Constructive procurement guidance

- Ask for demonstrated settings windows: not one recipe, but the stable range of force and penetration that holds flatness.

- Verify “after-process stability”: cut coupons and re-check flatness after slitting/laser cutting to expose residual stress issues.

- Confirm multi-zone support: intermediate/support rollers should help distribute load and reduce local over-bending.

In our commissioning practice, the most repeatable programs rely on moderate penetration with sufficient bending cycles, not maximum force.

Closed-loop hydraulic control is the real differentiator in repeatability

Hydraulic drive is powerful, but what buyers should evaluate is control architecture: pressure control alone is not the same as force/position closed-loop control at the leveling points. Drift, oil temperature, and valve response influence day-to-day consistency more than the headline tonnage.

Questions that surface control quality in an RFQ

- Is the system controlling roller gap/penetration (position), cylinder force, or only hydraulic pressure?

- How is oil temperature managed and compensated (cooling, viscosity-aware tuning, warm-up routines)?

- What sensors are used (pressure transducers, linear scales, load cells) and how are they calibrated?

- Is there recipe management with material-linked parameters for quick changeovers?

For bulk production, repeatability is the profit lever: stable control reduces rework and downstream stoppages. This is exactly where we focus our hydraulic precision leveling solutions.

When “wide” is harder than “thick”: crown control and edge-wave suppression

Wide sheets often fail acceptance due to edge wave or center buckle driven by non-uniform stress across width. This is less about total force and more about how the machine maintains consistent bending across the width under load. Intermediate and support rollers exist for this reason: to stabilize working rollers and manage crown behavior.

What to validate for wide material programs

- Width-to-thickness ratio: high ratios magnify crown sensitivity and require stronger support roller strategy.

- Support roller zoning: more adjustment granularity improves correction of localized edge issues.

- Frame deflection under load: ask for deflection data at your target throughput and material strength.

A practical takeaway: specifying only thickness is insufficient reminders for wide-sheet success; include width, yield strength, and defect type in the purchase spec.

Material-specific tuning: aluminum, copper foil, high-strength steel, and titanium alloys

A single precision hydraulic leveling machines can process many alloys, but bulk buyers benefit from planning process windows by material family. Differences in yield behavior, springback, and surface sensitivity directly affect roller selection, lubrication, and cleanliness requirements. Hydraulic levelers can cover extreme ranges—0.1 mm to 60 mm—but the operating practices should not be treated as interchangeable.

Practical tuning cues by material family

- Aluminum: prioritize surface protection and stable friction; avoid pickup with disciplined cleaning and controlled contact pressure.

- Copper foil / ultra-thin: focus on roller finish, tension handling, and vibration control; small disturbances can print through.

- High-strength steel: frame stiffness and support roller strategy dominate; confirm the machine maintains settings under sustained load.

- Titanium alloys: expect higher springback; rely on multi-cycle bending and consistent temperature control for repeatability.

When we build programs for mixed-material plants, we recommend defining material-linked recipes to keep changeovers predictable.

RFQ data that prevents under-spec and over-spec (and shortens commissioning)

Bulk procurement risk usually comes from missing process context: vendors will either oversize a machine “to be safe” or undersize it based on thickness alone. A concise data package allows accurate selection and reduces commissioning time.

| Category | What to provide | Why vendors need it |

|---|---|---|

| Material definition | Alloy/grade, yield strength range, hardness (if available) | Determines springback and required bending energy |

| Geometry | Thickness range, width range, length, coil/plate form | Impacts roller pitch choice and crown/support strategy |

| Defect profile | Edge wave/center buckle/crossbow/coil set; defect wavelength if known | Aligns roller configuration to actual flatness problem |

| Target outcome | Flatness metric + measurement method + acceptance sampling | Prevents commissioning disputes and mismatched expectations |

| Throughput | Line speed, takt time, batch size, changeover frequency | Determines automation level, hydraulic response, recipe handling |

| Downstream constraints | Cutting/welding/pressing steps, allowed residual stress risk | Guides “force vs cycles” strategy for stable parts |

A complete RFQ data pack is often the fastest way to reduce total project cost—not by choosing the cheapest machine, but by avoiding misfit and rework.

Maintenance that protects precision: oil cleanliness, roller wear, and calibration discipline

Precision leveling is sensitive to small changes in friction, roller geometry, and hydraulic responsiveness. Many “mystery flatness issues” trace back to oil contamination, gradual roller wear, or drift in measurement references rather than the leveling concept itself.

Preventive practices that preserve accuracy

- Oil cleanliness management: filtration and sampling reduce valve sticking and force instability.

- Roller inspection: monitor surface pickup, micro-pitting, and diameter changes that alter effective penetration.

- Sensor calibration: pressure/position feedback is only as reliable as its calibration routine.

- Cleaning discipline for non-ferrous: prevents embedded particles from printing defects into the sheet.

| Interval | Focus item | Why it matters |

|---|---|---|

| Per shift | Roller cleaning and visual surface check | Prevents pickup-related marking and friction drift |

| Weekly | Hydraulic leak/temperature review; filter differential pressure | Stabilizes control response and reduces contamination risk |

| Monthly | Oil sampling; sensor sanity checks | Detects early drift before it becomes scrap |

| Quarterly | Roller geometry verification; alignment inspection | Protects repeatability under high-volume operation |

From a buyer’s standpoint, maintenance is part of your flatness capability; it should be planned alongside spare parts and training.

Integrating a precision leveler into an intelligent production line

For bulk production, the leveler rarely stands alone. The best ROI appears when the leveling program, material tracking, and downstream equipment (decoiler, feeder, shear, stacking, inspection) share data. This is where intelligent line systems reduce variability and operator dependence.

Integration details that buyers should specify

- Recipe handoff: material ID triggers leveling parameters automatically to cut setup time.

- Upstream tension stability: decoiler/feeder control affects apparent flatness and repeatability.

- Downstream inspection loop: link flatness measurement feedback to program refinement (where applicable).

- Data logging: store key parameters (force/position, speed, temperature) to trace defects and reduce scrap.

As an integrated manufacturer of precision hydraulic leveling machines and line systems, we design the interfaces so your throughput gains are real, not theoretical.

Surface integrity matters: prevent roller marks, pickup, and micro-scratches

Bulk buyers in automotive parts, elevator components, and precision sheet-metal finishing often reject material not for flatness, but for surface defects introduced during leveling. Root causes are usually contamination (embedded particles), insufficient cleaning discipline, improper roller surface condition, or excessive localized contact pressure.

Practical controls that reduce surface-related scrap

- Define allowed surface roughness and finish targets for working rollers for your sensitive alloys.

- Implement staged cleaning: upstream wipe/brush + periodic roller cleaning to prevent pickup buildup.

- Control contact pressure: prefer settings that achieve flatness without “over-penetration” when surface is critical.

- Plan for non-ferrous handling: aluminum and copper require stricter contamination control than general steel work.

In acceptance testing, include both flatness and surface criteria so the line is validated for usable parts, not just “flat sheets”.

English

English русский

русский Español

Español عربى

عربى