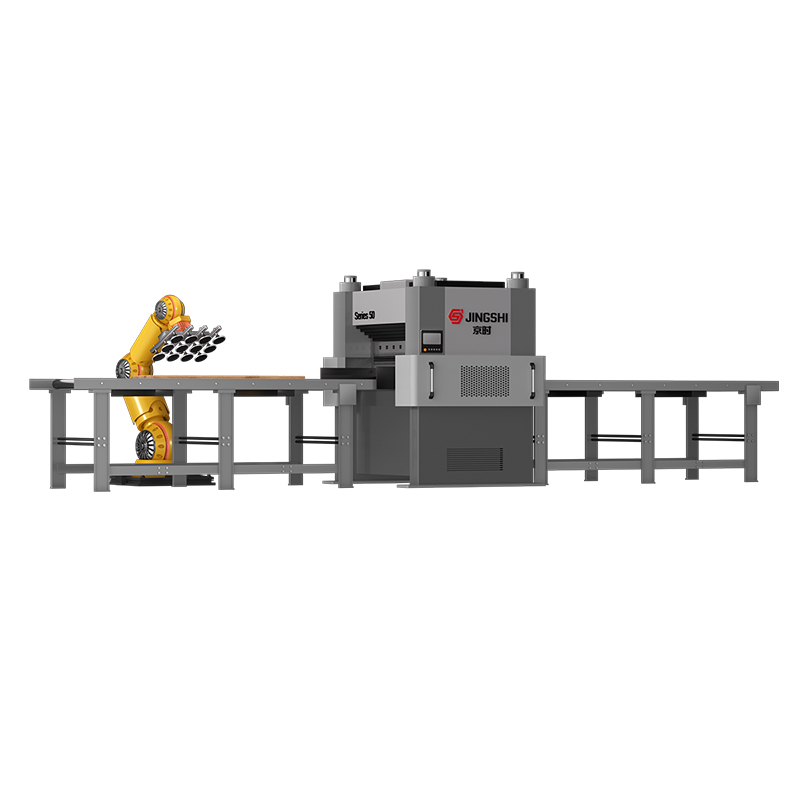

32 Series Thin Plate Hydraulic Servo Precision Leveling Machine

In fields demanding high flatness requirements, such as precision sheet metal processing, electronic device housings, and medical device components, the 32-series thin-plate hydraulic servo precision leveling machine, with its golden combination of hydraulic drive and servo control, has become an indispensable core processing equipment. This leveling machine, specifically designed for 0.3-3mm thin metal sheets, translates ±0.02mm leveling accuracy into stable product quality, fundamentally eliminating pain points such as deformation and wrinkling that easily occur in thin-plate processing.

Its standard configuration of 11 or more rollers arranged vertically, combined with high-wear-resistant roller surfaces of HRC58-62, and precise hydraulic control of 0.8-1.2Mpa, can efficiently adapt to batch processing of various materials such as stainless steel, cold-rolled steel, and aluminum sheets, and flexibly respond to small-batch customization needs. The intelligent pressure adjustment system automatically matches the pressure according to the sheet thickness, and the digital display shows key parameters in real time and supports storage and retrieval. Combined with its compact design, the equipment saves production space while significantly reducing maintenance costs, perfectly meeting the high-efficiency needs of precision machining scenarios.

- Specification

- About JINGSHI

- Contact Us

| Thickness / Width | 32-300-23 | 32-500-23 | 32-1000-23 | 32-1300-23 | 32-1600-23 |

| 0.5-1.5 | 300 | 500 | 1000 | 1300 | 1600 |

| 2 | 225 | 375 | 750 | 975 | 1000 |

| 2.5 | 150 | 250 | 500 | 700 | 800 |

| 3 | 110 | 180 | 400 | 450 | 550 |

Our core team brings over a decade of expertise in metal forming and finishing, mastering system-level R&D from structural design to hydraulic control and automation integration. We drive growth through technological innovation and continuous improvement.

Recommended Products

-

32 Series Thin Plate Hydraulic Servo Precision Leveling Machine

-

40 Series Heavy-Duty Hydraulic Precision Leveling Machine

-

50 Series Four-Column Hydraulic Intelligent Precision Leveling Machine

-

63 Series Thick Plate High-Efficiency Hydraulic Leveling Machine

-

80 Series Heavy-Duty Plate Hydraulic Ultra-Precision Leveling Machine

-

100 Series Large Workpiece Hydraulic Precision Leveling Machine

-

Fixed Power-Assisted Manipulator

-

Mobile Power-Assisted Manipulator

-

Suspended Power-Assisted Manipulator

-

Mobile Folding Arm Crane

-

Fixed Folding Arm Crane

-

Fixed Jib Crane

Our equipment is widely used in automotive parts, precision sheet metal, elevator components, agricultural machinery, saw blades, precision stamping, profile manufacturing, and electrical applications. Through continuous innovation and technical excellence, JingShi has become a trusted partner for manufacturers around the world.

-

Industry News

Industry News

2025.12.11

In the high-end manufacturing field, the leveling accuracy of sheet metal directly determines the qu...

2025.12.11

In the high-end manufacturing field, the leveling accuracy of sheet metal directly determines the qu... -

Industry News

Industry News

2025.12.11

It is understood that traditional hydraulic leveling machines generally suffer from pain points such...

2025.12.11

It is understood that traditional hydraulic leveling machines generally suffer from pain points such... -

Company News

Company News

2025.12.05

The company has long been dedicated to tackling advanced metal sheet finishing technologies, with it...

2025.12.05

The company has long been dedicated to tackling advanced metal sheet finishing technologies, with it... -

Company News

Company News

2025.12.05

The company adheres to its core “technology-driven” strategy, assembling a robust core team comprisi...

2025.12.05

The company adheres to its core “technology-driven” strategy, assembling a robust core team comprisi...

English

English русский

русский Español

Español عربى

عربى